Medical Equipment Breakdowns Are Preventable

A patient is receiving an important scan using some form of medical imaging equipment. Be it an MRI, CT, PET or some other highly sensitive imaging equipment, and the machine fails due to some unknown power issue. The expense needed to repair the machine combined with the patient still requiring vital information about their health is a heavy burden put on hospitals or equipment handlers.

One such case involves a mobile MRI System that is leased to hospitals. These systems require clean, high quality power in order to function properly. During a particular scan, a technician had noticed some flickering in the lights. The system was outfitted with a Power Analyzer and was monitoring the system for any anomalous activity. Shortly after, there seemed to be a malfunctioning part due to power issues that cost the MRI equipment company upwards of $20,000.

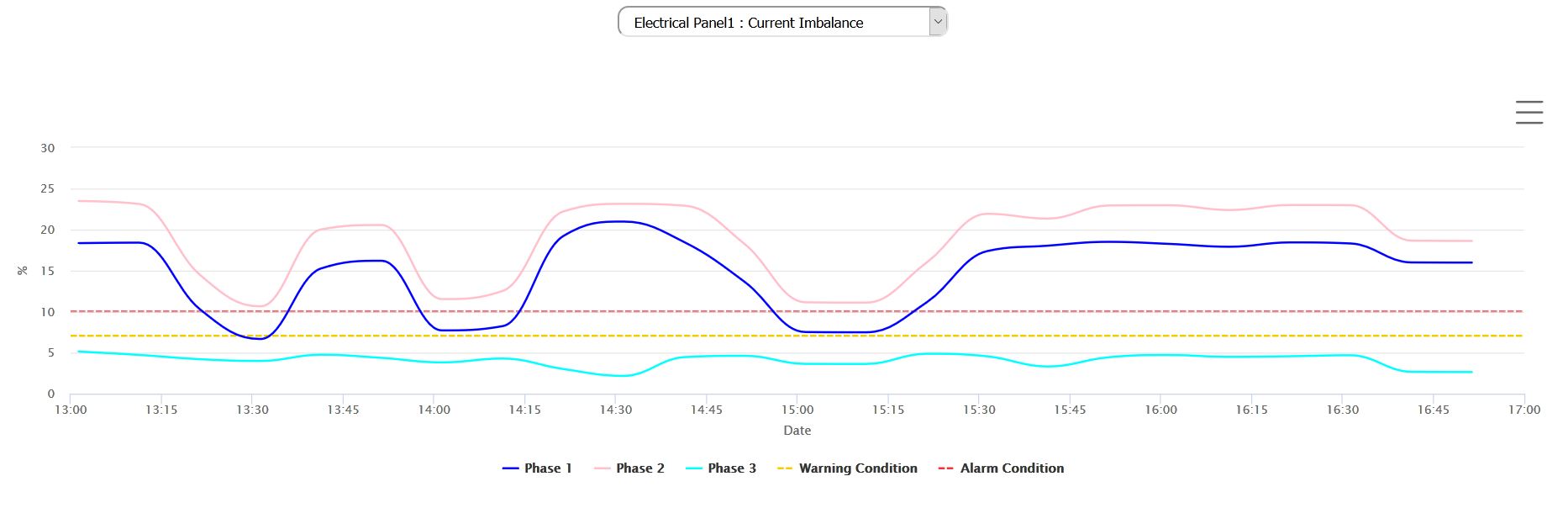

It is critical to be able to provide ways to mitigate these types of costly losses. The power analyzer did not find any anomalous activity during the time of the reported flickering, but there was an increased amount of total harmonic distortion (THD) within the current for some time previous and leading up to the event. A current imbalance of 22% and 17%, and a current THD of 22% and 18% for phases 2, and 1, respectively, can over time cause significant damage to the system. The leasing company had thought that the damage was due to dirty power coming in from the hospital, however upon further analysis, the voltage distortion and levels were quite clean with a small imbalance of 2.7% for phase one of the incoming line. Furthermore, there were no signs of under or over voltage, and voltage sags or swells. Relative to the current, the incoming power being clean was an indicator the issue was most likely internal to the system.

Figure 1. 3-phase current imbalance during the time of the reported flickering event taken from MachineSense Power Analyzer.

Figure 2. 3-phase current harmonic distortion during the time of the reported flickering event taken from MachineSense Power Analyzer.

With large imbalances within the current and the increase in harmonic distortion, these two factors may have been the killing blow for a critical part of the equipment. The current imbalances indicate an internal load balancing issue where there may be an incorrect use of loads on the imbalanced phases. The increased harmonic distortion may be a potential indicator that the incoming feed is undersized for the required power usage as the use of power at its peak will lend to increased harmonics. We have been able to learn that additional factors or gauges should be monitored such as voltage surge and voltage flickering, in order to provide a more robust solution to sensitive equipment that require high quality power.