3-Phase Power Quality Logger - 2 Port 30 - 300 Amps

The Power Analyzer electrical line monitoring system provides detailed power quality and energy consumption information for connected devices. Cloud based analytics and easy to understand dashboard gauges require no advanced training or expertise. Historical trends identify changing usage patterns, damaging power anomalies, and compare energy consumption between devices.

- Includes Power Analyzer Data Plan (6-Months Free)

- Includes Motor Analytics Package (6-Months Free)

- Includes Heater Bank Analytics Package (6-Months Free)

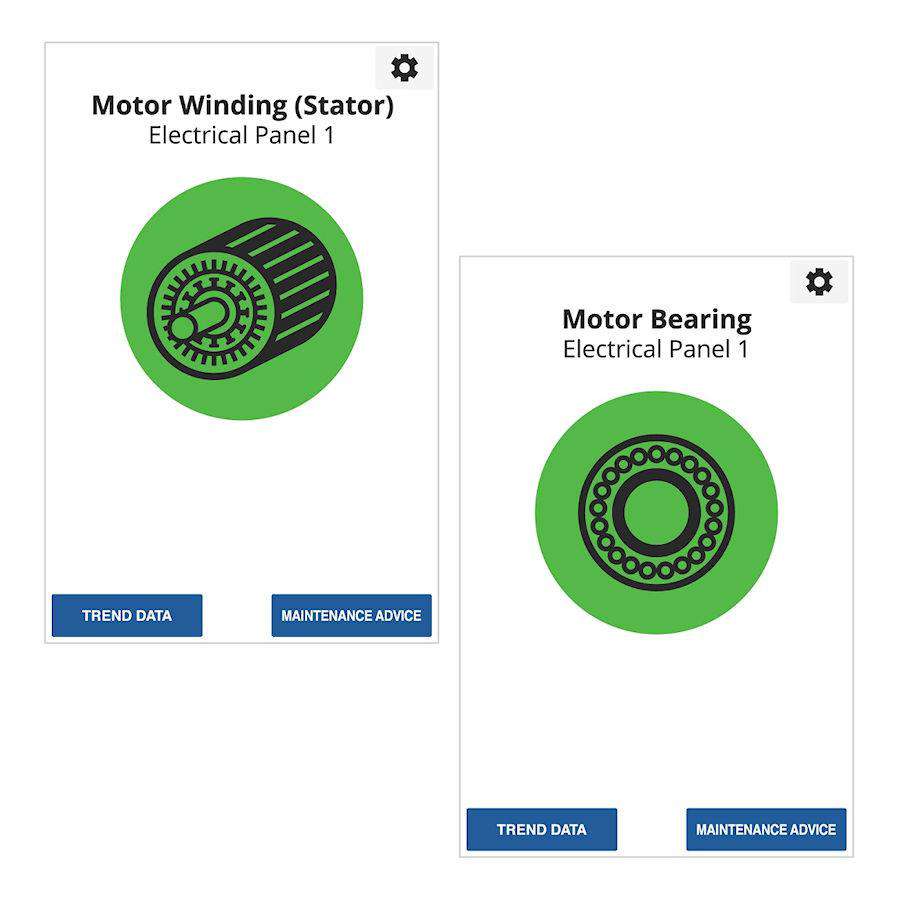

Power Analyzer electrical line monitoring system predicts the health of electrical motors and components, and provides detailed energy consumption information for connected devices.

Motor Analytics Package (6-Months FREE)

Heater Bank Analytics Package (6-Months FREE)

Power Analyzer is used by many manufacturing operations and facilities management as a predictive maintenance tool. The system is used in the energy services industry as a guide to understanding and optimizing electrical power consumption.

Power Analyzer measures and analyzes voltage and current on all three phases, power factor, active power and energy, reactive power and energy, voltage and current total harmonic distortion, neutral imbalance as well as sag/swell event detection. Unlike other power monitoring devices taking manual on-spot measurements, Power Analyzer is typically permanently connected to a device, to provide for constant monitoring.

The clip-on toroid sensors are easily attached to the input power line and constantly monitor the supply line. Sensor data is transmitted by the on-board Prophecy Datahub via WiFi or Ethernet to a local router and to Prophecy’s cloud infrastructure.

Returns

MachineSense wants you to be completely satisfied with your purchase. However, if you are unsatisfied, you can return your product within 60 days of purchase. Contact us at 443-457-1165 to start the return process.

Warranty

MachineSense offers COMPREHENSIVE PRODUCT WARRANTIES on all of our equipment. We warrant each MachineSense manufactured product to be free from defects in materials and workmanship, under normal use and service for the periods listed under “Warranty Periods”. The obligation of MachineSense, under this warranty, is limited to repairing or furnishing, without charge, a similar part to replace any part which fails under normal use due to a material or workmanship defect, within its respective warranty period. It is the purchaser’s responsibility to provide MachineSense with immediate written notice of any such suspected defect. Warranted replacement parts are billed and shipped freight pre-paid. The purchaser must return the suspect defective part, freight prepaid and with identifying documentation to receive full credit for the part returned. MachineSense shall not be held liable for damages or delay caused by defects. No allowance will be made for repairs or alterations without the written consent or approval of MachineSense.

The provisions in equipment specifications are descriptive, unless expressly stated as warranties. The liability of MachineSense to the purchaser, except as to title, arising out of the supplying of the said equipment, or its use, whether based upon warranty, contract or negligence, shall not in any case exceed the cost of correcting defects in the equipment as herein provided. All such liability shall terminate upon the expiration of said warranty periods. MachineSense shall not in any event be held liable for any special, indirect or consequential damages.

Commodities not manufactured by MachineSense are warranted and guaranteed to MachineSense by the original manufacturer and then only to the extent that Novatec is able to enforce such warranty or guaranty. MachineSense has not authorized anyone to make any warranty or representation other than the warranty contained here. Non-payment of invoice beyond 90 days will invalidate the warranty. A renewed warranty can be purchased directly from MachineSense.

Please note that we always strive to satisfy our customers in whatever manner is deemed most expedient to overcome any issues in connection with our equipment.

1-Year

Vacuum Pump Analyzer

Power Analyzer

This warranty shall not apply to equipment:

- Repaired or altered without written approval of MachineSense unless such repair or alteration was, in our judgment, not responsible for the failure.

- Which has been subject to misuse, negligence, accident or incorrect wiring by others.

- Warranty is void if processing rates exceed manufacturer-recommended levels or if damage is caused by ineffective power isolation and/or power spikes/sags or incorrect installation.

Get More Details

MachineSense Reviews Happy customers

Surprisingly reasonable cost

We are not a very large operation, so we were looking for something dependable and affordable that would help us to diagnose our problem. Your system seemed to be just what we were looking for and at a surprisingly reasonable cost.

System provides much more information

We were pleasantly surprised to find that the MachineSense Power Analyzer system provides much more information than we originally anticipated, such as power usage and cost to run each machine. Having the live information and the history available on a wireless mobile device is a big advantage as we can monitor the machine from anywhere and at anytime.

Always operating at peak efficiency

Due to the ease of hookup, the power analyzer was easily adaptable to suit our purpose. Overall, this is a very good product that will help us to monitor our equipment to make sure it is always operating at peak efficiency.

Designed to be simple and easy to understand

The Power Analyzer is designed to be simple and easy to understand, taking into account the fact that a scant few processors have electrical engineers on staff. I’m getting very high-level data presented in a very simple way.

Thermal screening performed quickly

Atrium Campus has integrated the breakthrough technology, Feverwarn, to its platform to allow for a thermal scanning capability within a university campus framework. With many universities planning to open in the Fall, basic thermal screening of the students, performed quickly and within the guidelines for social distancing, will be an absolute essential feature of a university's building access protocols.

Nilanjan Saha CTO, Atrium Campus, US

Feverwarn is very versatile thermal scanner

Feverwarn is very versatile thermal scanner with a lot of connectivity options ( WiFi, Ethernet etc) to get the data out. Use of mobile and web app have facilitated a lot of important functionality. They have adapted a lot of new IoT concepts to build this system